Paccurate Blog

Page 4

How Packing and Packaging Combined Impact Parcel Spend

Paccurate and Reveel recently formed a partnership to help shippers gain an edge in managing parcel spending to help improve shipping efficiency.

Read the Article

Why Volume Utilization Isn't Always King

When it comes to parcel shipping, businesses are perpetually searching for ways to reduce costs even as UPS and FedEx increase their general rates on a yearly basis. This has companies evaluating all aspects of the process, from packaging and packout optimization to reducing materials waste and carrier diversification.

Read the Article

Frequently Asked Questions About Optimizing Parcel Fulfillment

We compiled some of the most frequently asked questions (FAQs) from prospects and ultimately customers. When faced with sustainability initiatives or budget cuts, optimizing packing and packaging often gets overlooked. Take a look at these FAQs to understand how easy it is to implement Paccurate’s Packing Control System (PCS) for cutting transportation spend, reducing corrugated usage, and shipping less air.Question: What happens if I don’t have stock keeping unit (SKU) dimensions?

Read the Article

Paccurate Announces a New Seed Round

The Paccurate Team is excited to announce a $3.5MM Seed round, led by Tech Square Ventures. This new funding will allow us to further build out our packing intelligence platform, and advance the mission of reducing waste in the Supply Chain.

Read the Article

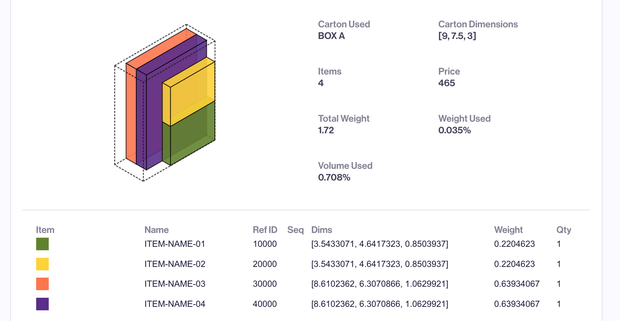

Building a Pack Legend with the Paccurate API

Making a pack request to Paccurate is straightforward: give us some items and some cartons to put them into, and we will cartonize those items. How customers consume the pack response is up to them: save the box assignment back to their ERP system, capture the estimated cost and use it to make a shipping decision, or even render an image of the items in their assigned boxes.

Read the Article

Extreme Makeover: Paccurate Edition

The Paccurate Product Team is excited to announce the release of our new and improved Paccurate Management Portal. We’ve taken the time to not only give a facelift to the existing manager but also to add a few exciting new features.

Read the Article

ShipStream CEO Colin Mollenhour Discusses Cartonization for 3PLs

Editor's note: ShipStream is a Paccurate Partner. We sat down with ecommerce veteran and logistics and WMS expert Colin Mollenhour. He explains how ShipStream started and discusses trends and operational issues impacting 3PLs doing business within complex supply chains.Please tell us how you got into shipping and co-founding the ShipStream start-up.

Read the ArticleSeed Funding Announcement

The Paccurate Team is beyond thrilled to announce our $2.2m seed round!

Read the Article

How to Ship Efficiently with Multi-Carrier Shipping Software

So far, 2022 has proven to be a fantastic time for millions of online shoppers who continue their voracious online shopping. It's a heady time, with solid GDP and jobs growth overlaying two years of ongoing economic disruption.

Read the Article